The advance comes from a study led by Eduardo Gracia, a researcher in Umeå University’s Department of Physics. The results were recently published in the prestigious Journal of Communications Engineering.

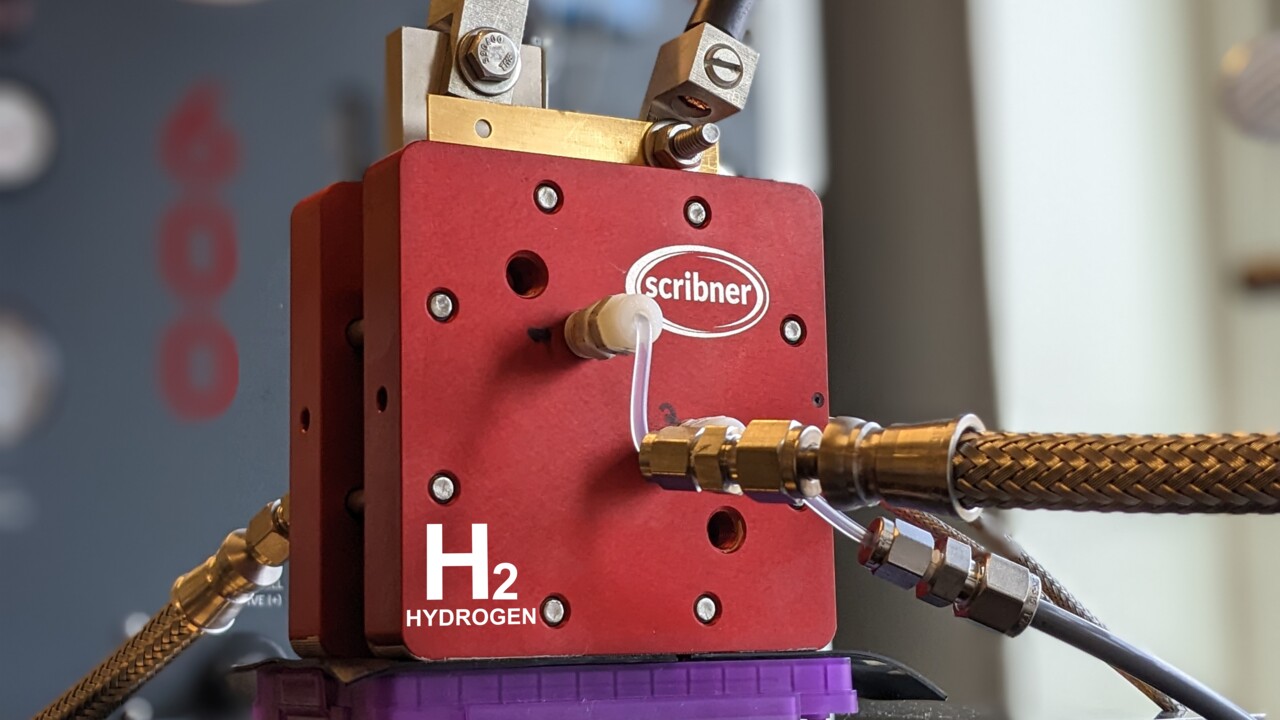

Hydrogen is an excellent energy source that can be used to replace fossil fuels. It is produced through a process called water electrolysis, in which water is broken down into hydrogen and oxygen. The process requires an electrocatalyst to facilitate the reaction, and today the most efficient technique for this process is proton exchange membrane (PEM) water electrolysis.

A problem that needs to be solved

But producing hydrogen via PEM water electrolysis is very challenging – it requires the use of precious metals such as platinum, ruthenium and iridium. Not only are these metals expensive and in limited supply – ruthenium and iridium also degrade over time.

– Fractionation of precious metals, a phenomenon called “metallurgy” reduces the efficiency of hydrogen production. It is a problem that needs to be solved so that we can fully benefit from PEM technology, says university lecturer Eduardo Gracia.

Explanation of terms

Water electrolysis: The process of using electricity to split water into its components, hydrogen and oxygen.

electrocatalyst: A substance that participates in an electrochemical reaction to increase the rate of the reaction.

stability of precious metals

If PEM technology is to be the driver for the transition to a more sustainable society, we must first address the extreme degradation of electrocatalysts. but how? Well, by trapping the very energetic but expensive metal in stable but inactive “scaffolding”.

This is where the breakthrough of Omeo researchers comes into play. The research group, led by Eduardo Gracia, has developed a new “scaffold” — a type of support structure — that can keep precious metals stable even under challenging conditions.

The structure is made from a mixture of tin, antimony, molybdenum and tungsten (Sn-Sb-Mo-W) oxides, which have proven to be strong enough to protect not only the precious metals but also other components of the system from degradation during the process.

By ensuring that precious metals last longer, the researchers’ findings could make PEM technology more economical and efficient for large-scale renewable hydrogen production. This is an important step in the transition to a more sustainable society.

About the scientific article

Piñeiro-García, A., Wu, X., Rafei, M. et al. Protective scaffold of ruthenium quaternary mixed oxide during an oxygen evolution reaction in acidic media. Common Eng 2, 28 (2023). https://doi.org/10.1038/s44172-023-00080-5

“Extreme tv maven. Beer fanatic. Friendly bacon fan. Communicator. Wannabe travel expert.”

More Stories

Tobias from Oxlosund lives with obsessive thoughts: “There is a misconception about OCD”

Antibiotics save lives and represent safety –

Christine and Christina have a common goal: HeartLung